X

- No products in the list

Español

English

Español

English

LISTA DE VERIFICACION DE USO DE LAVAPLATOS

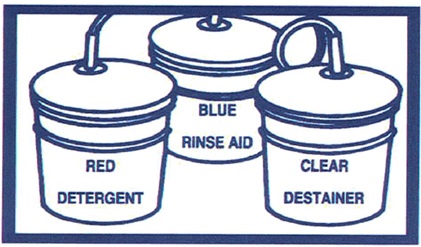

Verificar nivel de químicos

Al inicio de cada turno

AVISO PARA EL CLIENTE – DIEZ CONSEJOS PARA EVITAR CARGOS POR SERVICIOS,

Llamadas a servicio por causas y deficiencias del arrendatario como ser temperatura de agua, sistema eléctrico, falta de limpieza o abuso de uso en el equipo es pasible de cargos por tiempo, materiales y cargos por millaje bajo tarifas regulares del arrendador. El arrendador y sus representantes autorizados tendrán en todo momento derecho de acceso al equipo.EL ARRENDATARIO DEBE PROPORCIONAR ACCESO AL EQUIPO ENTRE LAS HORAS DE 8:OO AM A 4:00 PM, EN DÍAS DE SEMANA PARA EL SERVICIO DE RUTINA DEL EQUIPO. LA FALTA DEL ARRENDATARIO DE PROPORCIONAR ACCESO AL EQUIPO CONSTITUIRÁ UN INCUMPLIMIENTO DEL ARRENDAMIENTO QUE DA DERECHO AL ARRENDADOR A LOS RECURSOS DISPONIBLES SEGÚN EL CONTRATO.

El arrendatario será responsable de los problemas creados por los siguientes motivos:

WAREWASHING CHECKLIST

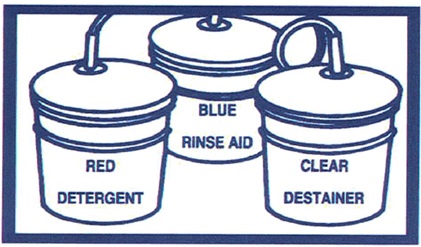

Check chemical levels

Beginning of shift

CUSTOMER NOTICE – TEN TIPS TO AVOID A SERVICE CHARGE,

A service call caused by a deficiency in Lessee’s water. temperature. electrical, cleaning, operation or abuse of Equipment is chargeable on a time plus material basis including mileage at the Lessor’s normal rates. Lessor and its authorized representatives shall at all times have a right of access to the equipment, THE LESSEE SHALL PROVIDE ACCESS TO THE EQUIPMENT BETWEEN THE HOURS OF 8•OO AM – 4:00 PM, WEEKDAYS FOR ROUTINE SERVICE OF THE EQUIPMENT. FAILURE OF THE LESSEE TO PROVIDE ACCESS TO THE EQUIMPMENT SHALL CONSTITUTE A BREACH OF THE LEASE ENTITLING LESSOR TO THE REMEDIES AVAILABLE UNDER CONTRACT

The lessee will be responsible for problems created by the following:

© 2024 American Energy Restaurant Equipment. | Privacy Policy | Terms & Conditions

703-644-6666 | 7532 Fullerton Ct. Springfield, VA 22153

Store Hours: Monday – Friday 9am – 5pm | Warehouse Hours: Monday – Friday 8am – 4pm (for customer pickup) | Se Habla Español